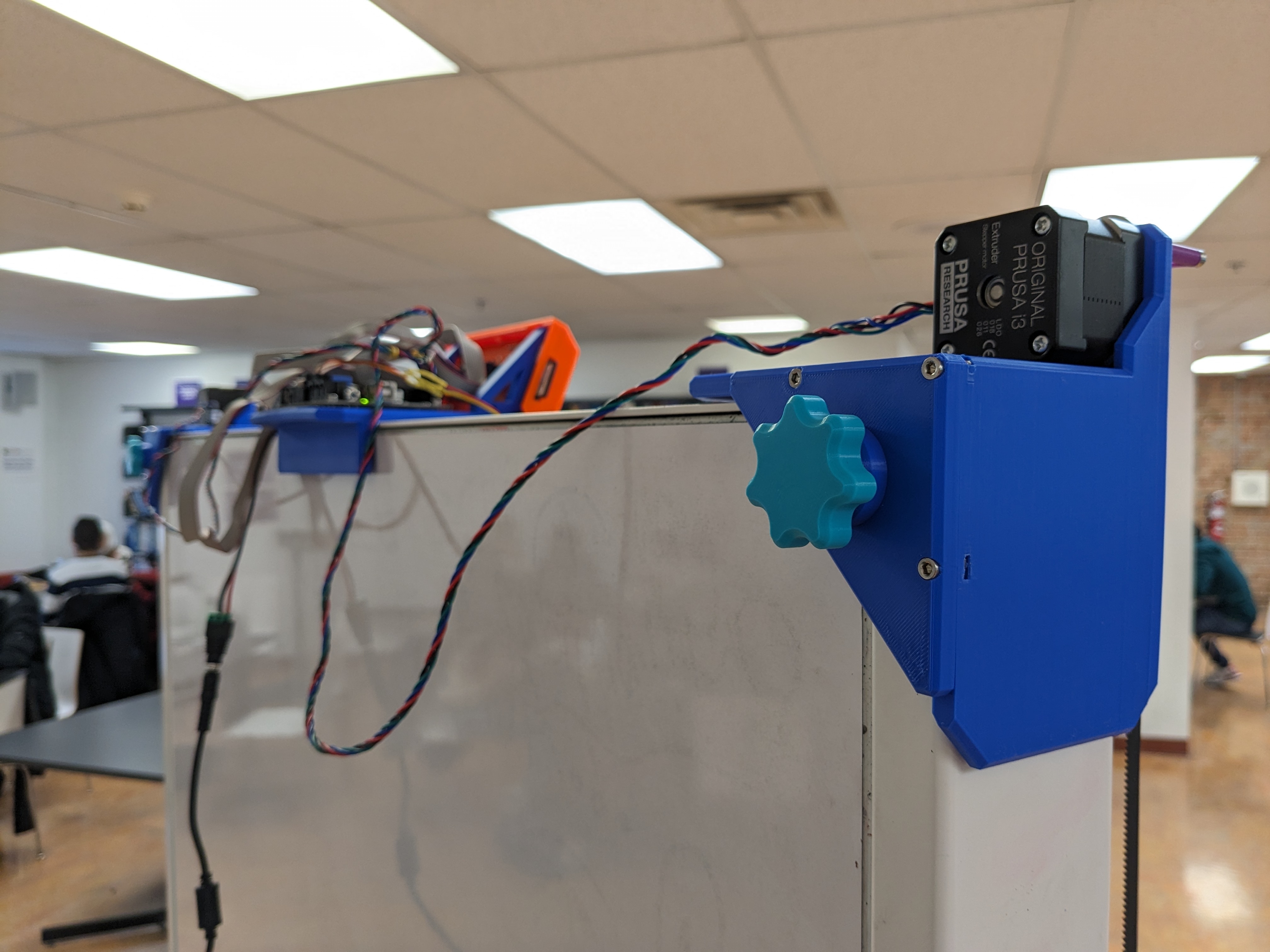

I upgraded two Prusa MK3s to MK3.9, and ended up with a couple of spare boards, stepper motors and a bunch of other things. So I decided to turn them into a Makelangelo clone!

Since the school I work at had these large standing whiteboards, I designed and printed corner brackets to hold the motors, as well as a base for the electronics.

I’m still having trouble with the homing process, but very happy with the results so far!

I’ll be posting the firmware and 3d printed files online soon.

What the what? Did you just turn a 3d printer into a 2d printer? This is amazing! Only a 1d printer would astonish me more!

… Would that be a seismograph?

Im afraid it would just be a thing that makes perfectly straight lines :(

That you couldn’t see, since they’d have no thickness, only length

Maybe a printer that adds Morse code on a string.

--- ·-· – ·- -· -·– ·-·· ·· -· · ···

That’s still 2 dimensions.

How do you keep the pen tips vertical position accurate as it pens around without something dragging in the drawings?

I’m not perfectly sure I understand your question, but if you see it in action, this thing is really wobbly. Not much precision there.

I was basically just asking how wobbly it is, haha.

Way cooler than the one I built a few months ago, but I didn’t reuse parts of a Prusa! 😮

Nice! Can’t take all the credit for mine, most of the work was done by Dan for the Makelangelo.

You’re amazing

Haha, can’t take all the credit here, I just modified the Makelangelo to work with the parts I had!

That’s really cool!

So are the vertical cutoffs either side the result of string length, or what’s going on with that?

It can go further than that, i just limited it to a smaller size for my first real test. I told the software that I was drawing on an A1 sized paper. Drawing this across the full board would have taken forever.

There are a couple of no-go zones close to the corners. Longer belts would allow it to go lower, but then the counterweights would hit the floor when going up high and limit the drawing area there instead.

Would a block and tackle solve that problem? Could 3d print them likely.

Hmmm, only if a second pulley was higher than the motor, I imagine.

You can use multiple pulleys and shackles to take the distance of the rope up.

It’s how they do it inside of machines as far as I’ve seen.

I still feel the distance they travel will stay the same. Except if I use a gear train.

Using #4 would allow you to move the pen 40cm for every 10cm of counterweight travel.

Ah yes, different sized pulleys would work the same as the gear train I had in mind. Thanks for the explanation!

Edit: on second look, it’s more complex than that, as the weight is not connected to the end of the rope, but on a pulley.

neato. Cool project.